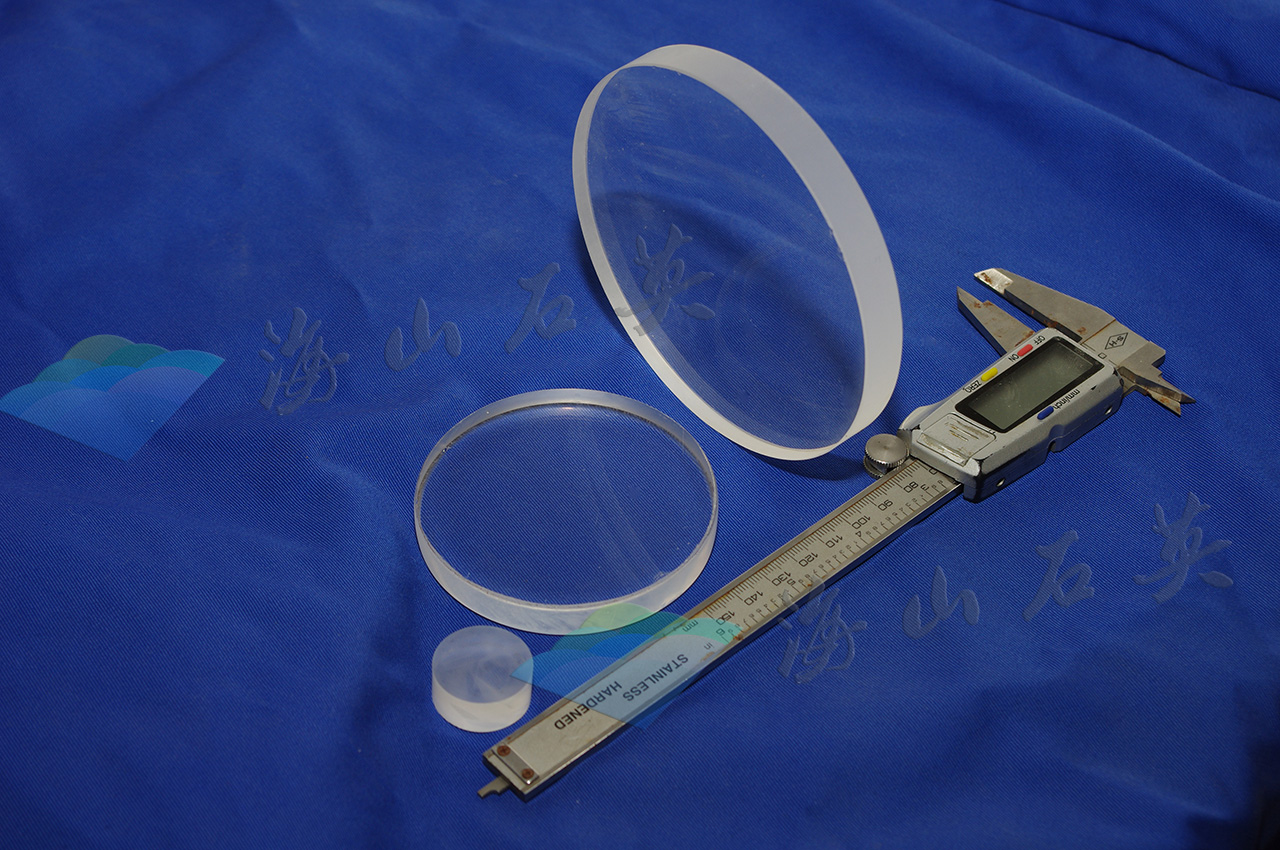

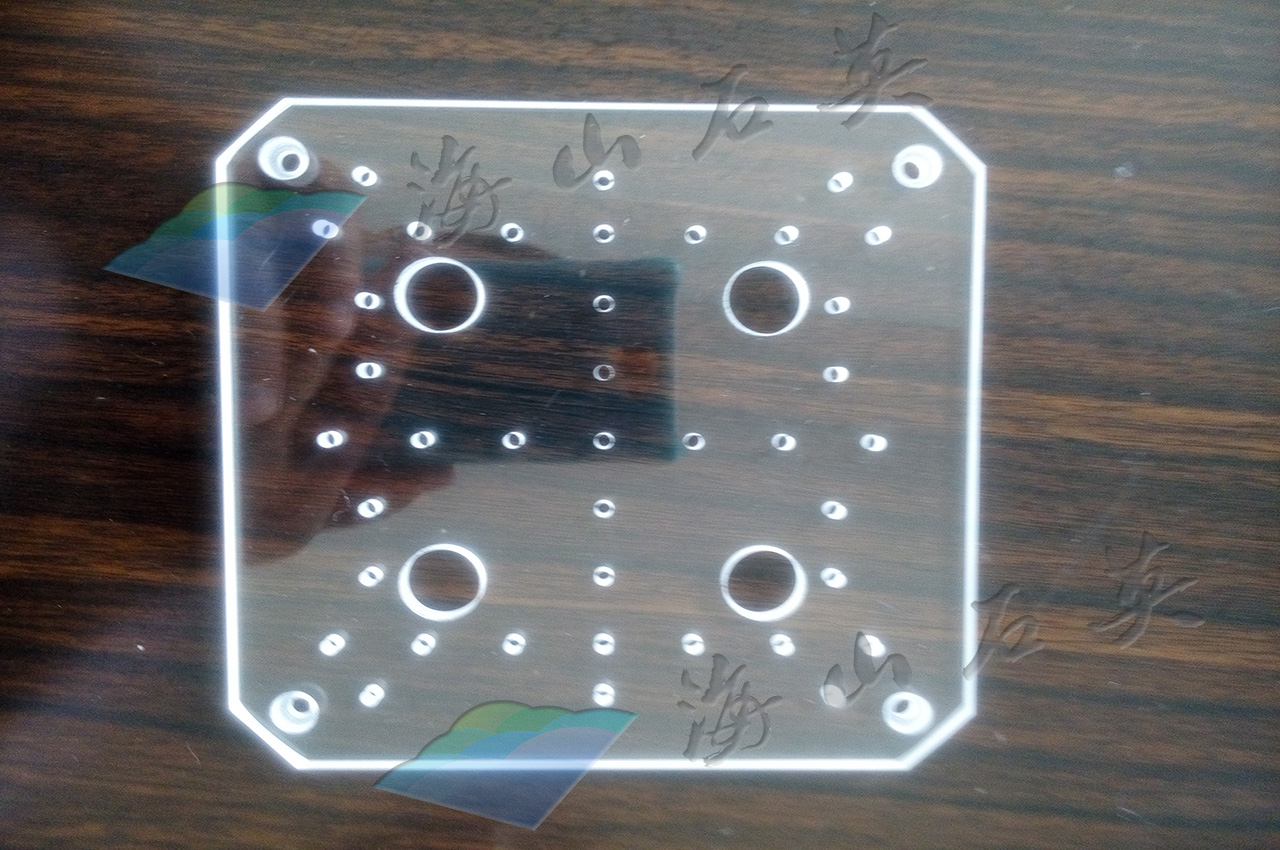

Haishan Quartz adopts the method of continuous melting to produce quartz glass plates, which are sliced and polished to become quartz wafers. With a silicon dioxide content of over 99.999%, a Mohs hardness of seven, visible light transmittance of over 90%, it has characteristics such as high temperature resistance, low coefficient of thermal expansion, good thermal shock resistance, and electrical insulation properties. It can be processed into lenses, prisms, and various other shapes. Widely used in the production of optical instruments, semiconductor auxiliary materials, high-frequency circuit board substrates, high-temperature resistant windows, medical equipment, and chemical instruments resistant to high-temperature and acid corrosion.

Learn about Quartz Glass Characteristics

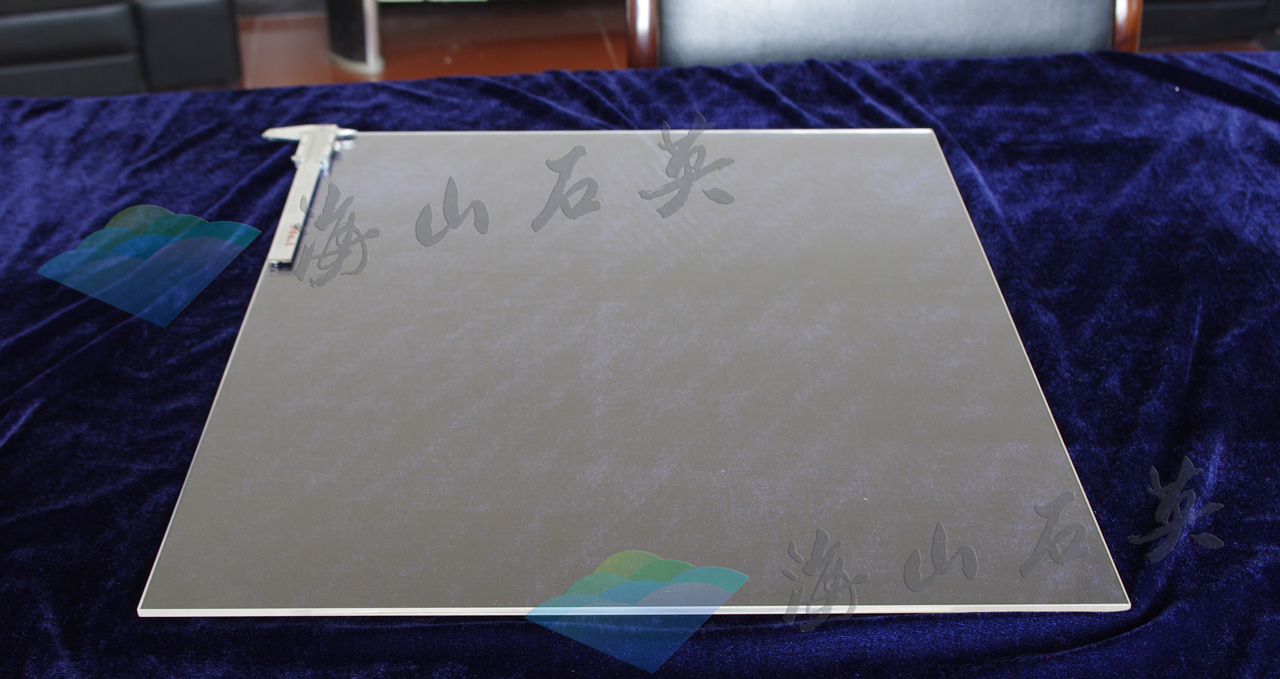

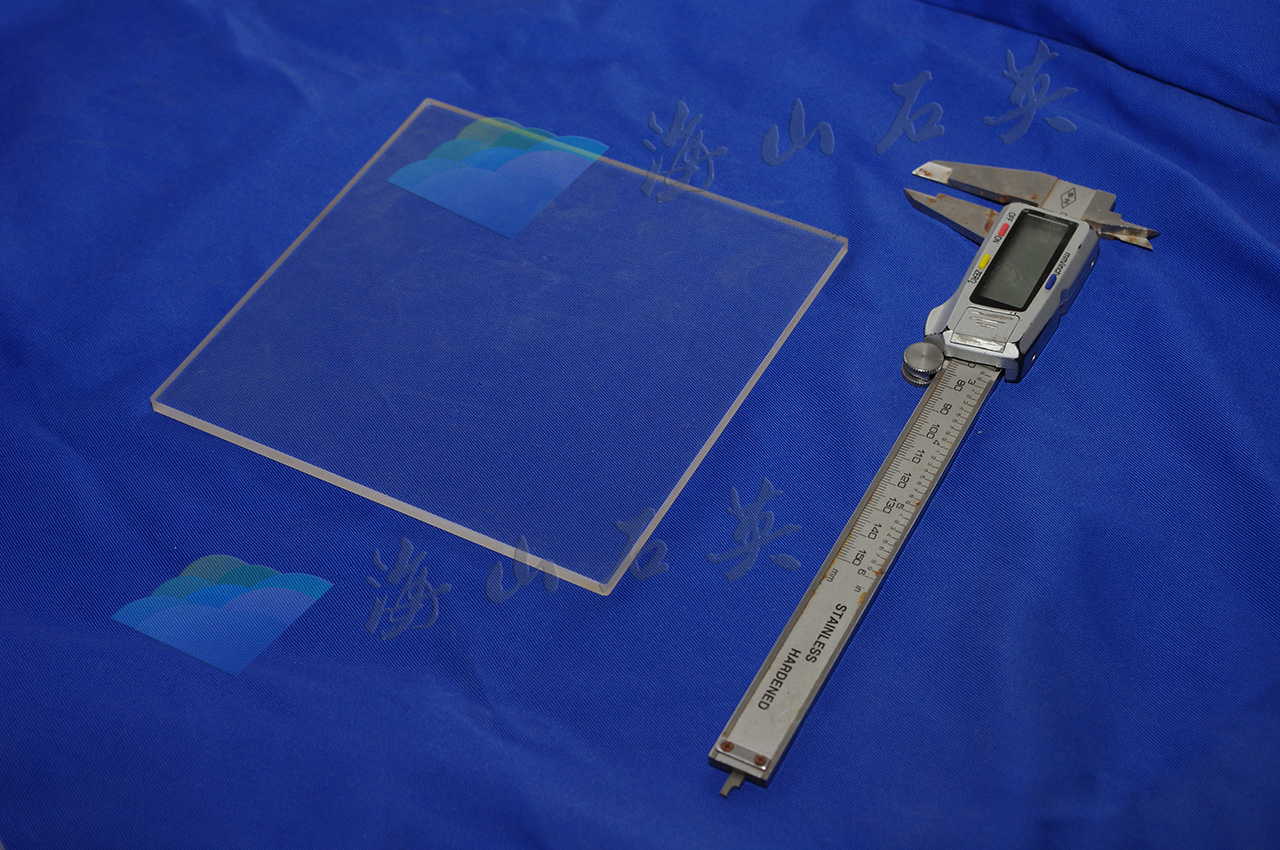

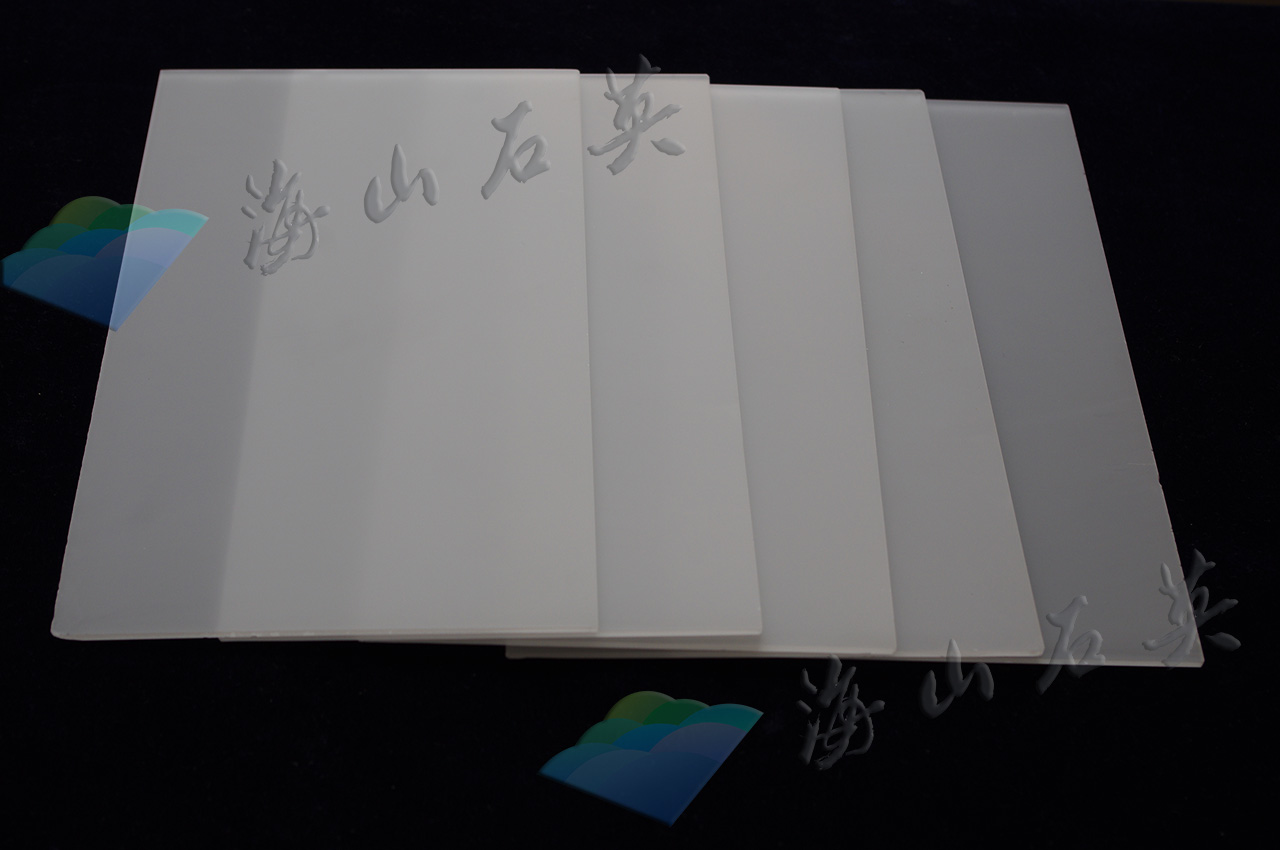

Large Size Quartz Glass Plates

Haishan Quartz and its affiliated enterprises have invested a lot of effort in the research and development of large-size quartz glass plates and quartz wafers, and can produce quartz glass plates with dimensions of 1000mm * 2000mm, leading the domestic level in technology.

Haishan Quartz and its affiliated enterprises hold 3 patents related to large-size quartz glass plates: CN2841652 (continuous melting furnace for drawing quartz glass plates), CN104445872A (a new type of continuous melting furnace for drawing quartz glass plates), CN104418503 (a continuous melting furnace for directly drawing filter UV quartz glass plates).

Conventional Quartz Glass Plate

Quartz glass plates can be processed according to customer requirements, including dehydroxylation, sanding, drilling, cutting, grooving, etc.

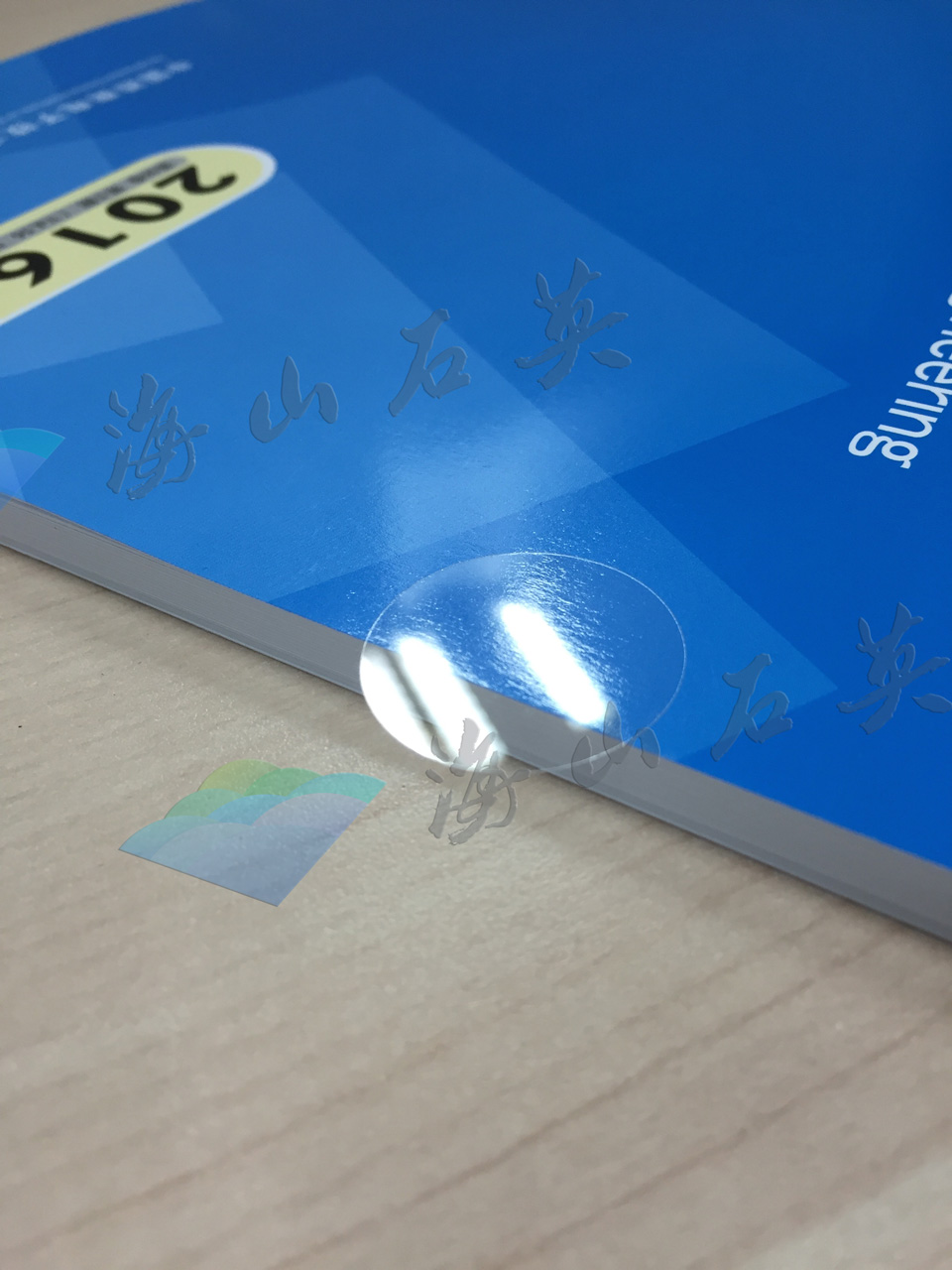

Ultra-Thin Quartz Glass Sheet

Haishan Quartz employs imported grinding machines from Japan to provide ultra-thin quartz glass sheets with a thickness of only 0.1±0.005 mm (outer diameter 1~1.5 inches).